Introduction to the advantages of silicone fireproof sleeve

Author:admin Addtime:2020-10-28 15:10:40 Click:

Silicone protective sleeve is welcomed by consumers for its unique performance, so what are the advantages of silicone fireproof sheath? Let me explain it in detail below.

1. Safety protection to protect the health of workers

The alkali-free glass fiber itself has strong tensile strength, will not be wrinkled and broken, is resistant to vulcanization, is smoke-free, halogen-free, non-toxic, pure oxygen, non-combustible, and has good insulation characteristics. After the organic silicone is cured, its safety and environmental protection performance is strengthened and effectively protected Workers are healthy and reduce the incidence of occupational diseases. Unlike asbestos products, which are extremely harmful to the human body and the environment.

2. Superior high temperature resistance

The silicone structure on the surface of the fire protection jacket contains both "organic groups" and "inorganic structures". This special composition and molecular structure makes it integrate the characteristics of organic substances and the functions of inorganic substances. Compared with other polymer materials, its most prominent feature is its high temperature resistance. With silicon-oxygen (Si-O) bond as the main chain structure, the bond energy of C-C bond is 82.6 kcal/mole, and the bond energy of Si-O bond is 121 kcal/mole in organosilicon, so Its thermal stability is high, and the chemical bonds of molecules will not break or decompose under high temperature (or radiation exposure). Silicone is not only resistant to high temperatures, but also resistant to low temperatures, and can be used in a wide temperature range. Whether it is chemical properties or physical mechanical properties, the change with temperature is very small.

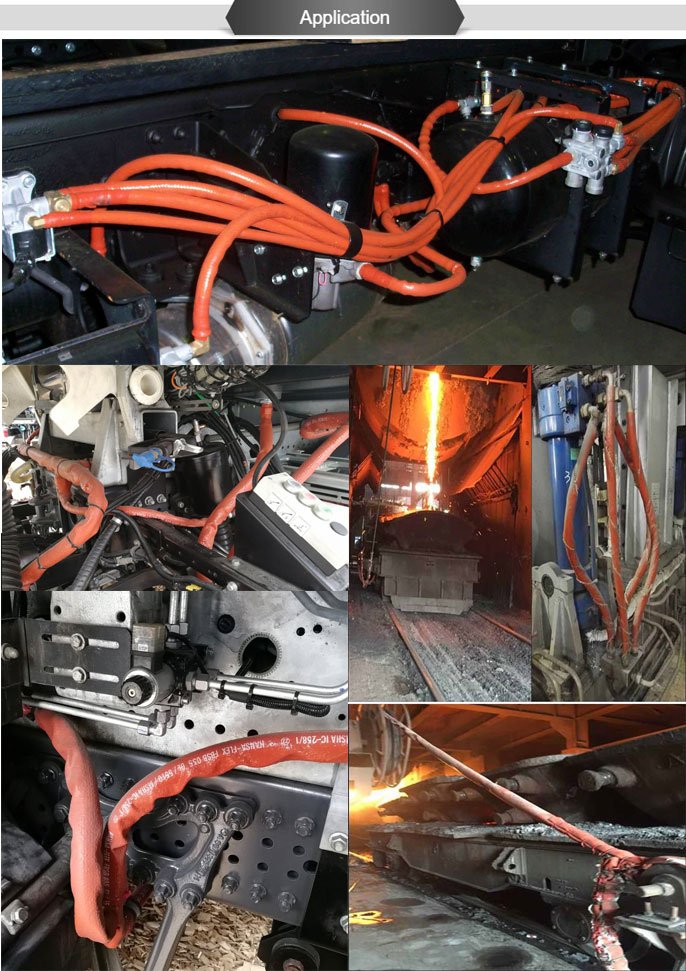

3. Splash-proof, multiple protection

In the smelting industry, the temperature of the medium in the electric furnace is extremely high, and it is easy to form high-temperature splash (the same is true in the electric welding industry). After cooling and solidification, slag is formed on the pipe or cable, which will harden the rubber on the outer layer of the pipe or cable, and finally Embrittlement and cracking. Furthermore, unprotected equipment and cables are damaged. The Baite brand fire-resistant jacket coated with multiple layers of silicone can achieve multiple safety protections. The maximum temperature can be as high as 1300 degrees Celsius, which can effectively block molten iron, molten copper, molten aluminum, etc. Splashing of high-temperature molten material prevents damage to surrounding cables and equipment.

4. Thermal insulation, energy saving and consumption reduction, radiation resistance

In high-temperature workshops, many pipes, valves or equipment have very high internal temperatures. If they are not covered with protective materials, it is easy to cause burns or heat loss. Better-branded fireproof sheath has better thermal stability, radiation resistance and thermal insulation than other polymer materials, preventing accidents, reducing energy consumption, and preventing the heat of the medium in the pipeline from being directly transferred to the surrounding environment The temperature of the workshop is too high, saving the cost of cooling