Introduction to metal and spiral protective sleeve

Author:admin Addtime:2019-11-13 10:33:39 Click:

There are two kinds of protection springs sold on the market: one is a traditional metal spring, which is processed by a professional machine by carbon spring steel wire or stainless steel spring wire, and then plated at one end. The other is a spiral protective sleeve made of polypropylene (PP) as a raw material, which is made by hot-spinning and setting extrusion process. It is a new type of product that replaces the traditional metal protection spring for hose protection. In use, a short length of hose can be wound from one end to the other, and a longer hose can be wound from the middle to the ends. Although both protective springs can be used on the outside of mechanical hoses and tubing to extend the life of the internal product, they differ in the following ways:

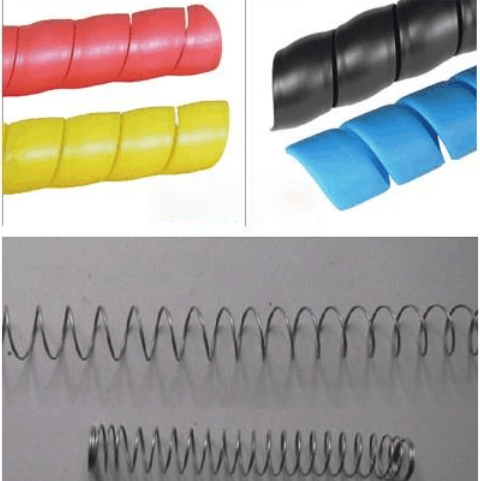

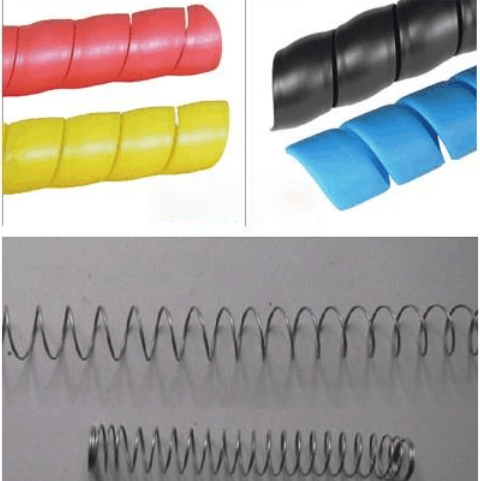

First, from the appearance

It can be seen from the picture that the metal wire of the metal retaining spring is relatively thin and has a large gap, which does not protect the product well, and the wire will cause damage to the hose during the friction process of the hose. The spiral protective cover is available in various colors, and can be selected according to the occasion and the preference. The inner side is a flat surface, the outer side is a flat surface, and the outer side is a curved surface. According to the use environment, the gap is relatively small, and the internal product can be well protected.

Second, from the performance

The metal spring elastic is super strong, tensile strength is very good, but this is also its shortcomings, the greater the stretch, the larger the gap, the more the internal products can not protect. The spiral protective sleeve adopts modified plastic and has good resistance to high and low temperature, oil resistance, ultraviolet resistance, antistatic, impact resistance, abrasion resistance, corrosion resistance, acid and alkali resistance, aging resistance, etc., and has good elasticity. And the tensile force plays a significant protective effect on the internal products such as the hose, and is easy to operate and easy to install.

Third, the scope of use

Metal retaining spring is mainly used for mechanical hoses and oil pipes. The spiral protective cover can also be used on various indoor and outdoor cables, which can be used for the cable to be well restrained and anti-static. It can also be used as an air-conditioning pipe protection cover, a gas station oil pipe protection cover, and a gas station gas pipe. Protective cover, car wash hose protection tube, etc.

In general, the spiral protective cover has the advantages of a metal retaining spring, which improves the shortage of the metal retaining spring. It will better protect the internal products and will play a role in more and more places.